Enterprise Resource Planning (ERP) in supply chain management has become a vital component for businesses looking to thrive in a rapidly evolving market. Understanding what ERP supply chain management entails and why it’s critical in today’s business world sets the stage for a deeper exploration of its transformative impact.

The Evolution of ERP Supply Chain Management

Initially, supply chain management was heavily reliant on traditional methods, which were often cumbersome and inefficient. The advent of ERP solutions revolutionized this field, introducing a more integrated and streamlined approach.

Early Stages: The Pre-Technology Era

In the initial stages, supply chain management was primarily manual and paper-based. Businesses managed orders, inventory, and logistics through physical records. This era was characterized by local and regional supply chains, limited by the constraints of slow communication and transportation methods.

The 1960s and 1970s: The Birth of Modern SCM

The concept of SCM as we know it today began to take shape during the 1960s and 1970s. The introduction of computers and the development of Enterprise Resource Planning (ERP) systems marked the beginning of integrating and automating supply chain processes. These technologies enabled businesses to manage operations more efficiently, though they were still largely confined to larger corporations due to the high costs of technology.

The 1980s: Globalization and Expansion

The 1980s saw the expansion of global trade, driven by deregulation and advancements in transportation and communication technologies. This era marked the shift from local supply chains to global networks, increasing the complexity of managing these chains. The focus shifted to optimizing the entire supply chain, rather than just individual components, leading to the development of more sophisticated SCM strategies and tools.

The 1990s: The Rise of Just-In-Time and Lean Manufacturing

The 1990s introduced concepts like Just-In-Time (JIT) and Lean Manufacturing, which emphasized efficiency and waste reduction in the supply chain. These methodologies sought to synchronize supply with demand, reducing inventory levels and improving response times. The adoption of these practices marked a shift towards more responsive and agile supply chain strategies.

The 2000s: Internet and E-Commerce Revolution

The advent of the internet and the rise of e-commerce in the 2000s transformed SCM. The digital revolution enabled real-time data sharing and communication across the global supply chain network. E-commerce demanded faster, more efficient, and more flexible supply chain processes to meet the growing consumer expectations for quick and reliable delivery.

The 2010s and Beyond: Advanced Technologies and Integration

The most recent phase in the evolution of SCM involves the integration of advanced technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and blockchain. These technologies offer unprecedented levels of visibility, efficiency, and automation. AI and machine learning provide predictive analytics for better demand forecasting, IoT enables real-time tracking and monitoring of goods, and blockchain offers a secure and transparent way to track transactions and manage records.

The Future: Sustainability and Resilience

Looking towards the future, the focus of SCM is shifting towards sustainability and resilience. Businesses are increasingly recognizing the importance of environmentally and socially responsible supply chains. Additionally, the COVID-19 pandemic highlighted the need for supply chains to be resilient to disruptions, leading to a renewed emphasis on risk management and contingency planning.

ERP Systems: A Game Changer

An ERP system is a software platform that combines various business processes and functions into a single unified system. In supply chain management, ERP systems offer unparalleled benefits, including enhanced efficiency and better resource management.

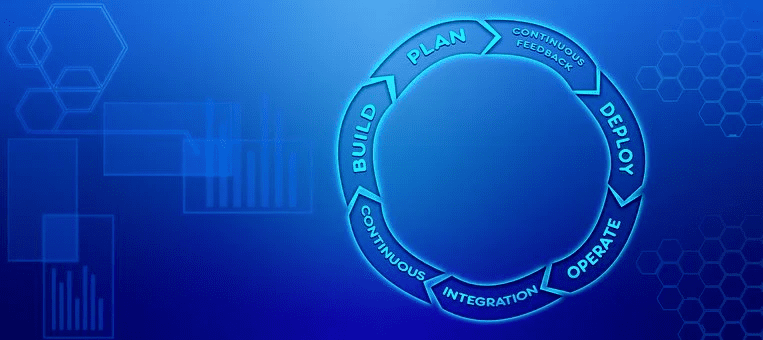

Integration of ERP in Supply Chain

The integration of ERP systems in supply chain operations aids in streamlining tasks and providing real-time data analysis. This integration is pivotal for businesses to stay agile and informed.

Enhanced Visibility and Control

ERP systems offer improved tracking and monitoring of supply chain activities. This level of visibility is crucial for informed decision-making and maintaining control over the entire supply chain.

Cost Reduction and Efficiency

One of the key advantages of ERP in supply chain management is the ability to automate processes, leading to significant reductions in operational costs and enhanced efficiency.

Scalability and Flexibility

ERP systems provide the scalability and flexibility needed to adapt to market changes and support business growth. This adaptability is essential for long-term success.

Risk Management and Compliance

Managing risks and ensuring compliance are critical aspects of supply chain management. ERP systems aid in identifying potential risks and maintaining compliance with various regulations.

The Role of Cloud-Based ERP Systems

Cloud-based ERP solutions offer enhanced accessibility and security, representing the future of ERP in supply chain management. These systems are becoming increasingly popular due to their scalability and ease of access.

ERP and Customer Satisfaction

Improving customer experience is a direct outcome of effective ERP implementation in supply chains. Various case studies demonstrate how ERP contributes to heightened customer satisfaction.

Challenges in Implementing ERP Systems

Despite the benefits, implementing an ERP system can be challenging, often met with resistance. Understanding these challenges is key to successful implementation.

Future of ERP in Supply Chain Management

The future of ERP in supply chain management is intertwined with emerging technologies. This section explores the potential advancements and predictions for ERP systems.

Choosing the Right ERP System

Selecting the right ERP system involves understanding key features and undergoing a thorough vendor selection process. This part of the article guides businesses on what to look for in an ERP system.

Implementation Strategies

Implementing an ERP system successfully requires adherence to best practices and avoiding common pitfalls. This section offers insights into effective implementation strategies.

Conclusion

In conclusion, ERP supply chain management is a critical tool for modern businesses. This article summarizes the key points discussed and looks ahead to the future of ERP in supply chain management.

FAQs

- What is ERP in supply chain management?

- ERP in supply chain management refers to the use of integrated software systems to manage and optimize the various processes within a supply chain.

- How does ERP improve supply chain management?

- ERP improves supply chain management by enhancing efficiency, reducing costs, improving visibility, and enabling better decision-making.

- What are the challenges of implementing an ERP system?

- Challenges include resistance to change, the complexity of integration, and the need for proper training and support.

- Can small businesses benefit from ERP systems?

- Yes, small businesses can benefit significantly from ERP systems, especially cloud-based solutions that are scalable and cost-effective.

- What is the future of ERP in supply chain management?

- The future of ERP in supply chain management is likely to involve more cloud-based solutions, integration with emerging technologies like AI and IoT, and increased customization.