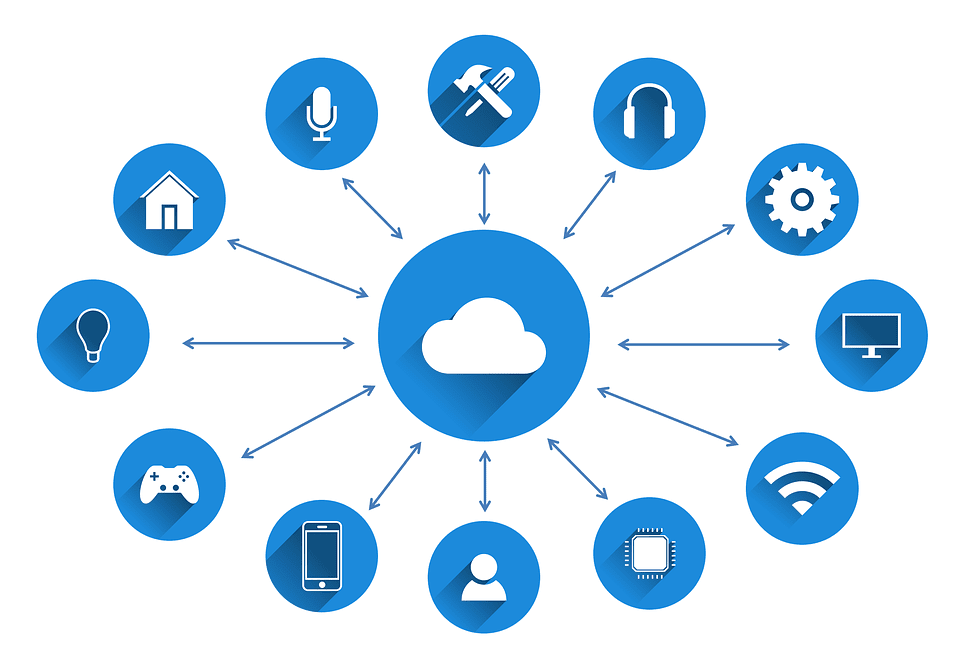

The Internet of Things or IoT is a technological innovation picking up steam across various industries. Much like the craze over artificial intelligence, the positive word of mouth around IoT is because of its potential to make tedious processes faster and more efficient. In a nutshell, IoT is a term for objects connected through embedded technologies. They communicate over their shared network, exchanging data that helps them function better.

While it has yet to unlock its potential fully, IoT has multiple functions that show how it can revolutionize the manufacturing industry in the future.

IoT is tied to cloud-based online services like NetSuite

The Internet of Things makes use of cloud-based services to carry out its functions over a network. One prominent example is NetSuite, an online platform that businesses and companies utilize to monitor and manage all transactions in a centralized manner. Companies have used NetSuite Consulting to keep track of inventory, monitor finances, and carry out customer service functions.

The integration of IoT and NetSuite allows manufacturers to recalibrate efforts to meet product quotas and delivery times. This is one way that IoT is changing manufacturers’ mode of operations.

IoT helps predict possible repairs

When it comes to a field as technical as manufacturing, there is a tendency for objects, equipment, or even products to come out in the wrong way. After all, mass production is not entirely foolproof. There are instances when machinery may fail due to a hardware problem. It is important to spot these right away to prevent hazards in the workplace.

Because of the automated nature of IoT, malfunctioning objects may be pulled out for repairs by managers right away. This process is not only safe and secure but also cost-efficient. By making repairs as soon as issues arise, excessive repair fees are avoided.

Logistics concerns are addressed as soon as possible

Manufacturers depend on transportation as well. Ingredients and necessary materials are imported from several places, and they must arrive on time. Neglecting delivery times will cause production delays, affecting business operations as a whole.

The IoT allows people to manage delivery methods in real-time and remotely. This functionality makes companies operate more efficiently, meeting demands at faster rates. IoT combines several functionalities, calculating costs such as fuel and labor instantly.

The power of Digital Twins

While the name might be pretty unconventional, the digital twins’ aspect of IoT is one of its most significant advantages. Prototypes can be replicated quickly, with added capabilities such as the prediction of capabilities and failures. Products can be assessed according to their quality even before they are produced in higher quantities.

What used to be a simple proof of concept can now be turned into a reality due to the efficiency of an IoT. Digital twins also enable the manufacturer to predict an item’s life span, making it easier for tweaks and fixes to be created as soon as they are needed.

IoT can conduct asset tracking

Asset tracking is one of the most crucial parts of manufacturing. This practice is integral in ensuring that business operations remain in top shape and that concerns are addressed as soon as they arise. Manufacturing is a high-speed business, and time truly means the money in this field. Using IoT to carry out asset tracking, desktop and mobile devices may be used to monitor supply chain deliveries.

The need for raw materials, boxes, canisters, and other items presents the importance of monitoring assets remotely. By tracking events in real-time, problems can be spotted and addressed efficiently.

Tracking using an IoT may be done through applications created explicitly for this purpose. The use of the app can change how logistics, stocks, and security are managed. These are all vital parts of the manufacturing process and the operations of any company as a whole.

There is no doubt that the IoT is a handy technological development. Pieces of technology attached or embedded into objects can help them communicate and exchange data even through a sizable distance. For manufacturers, this impressive innovation allows businesses to reach target goals without too many hands moving at the same time.

As technology continues to evolve, so does the industry. With the IoT, manufacturers will be a part of future developments to come.